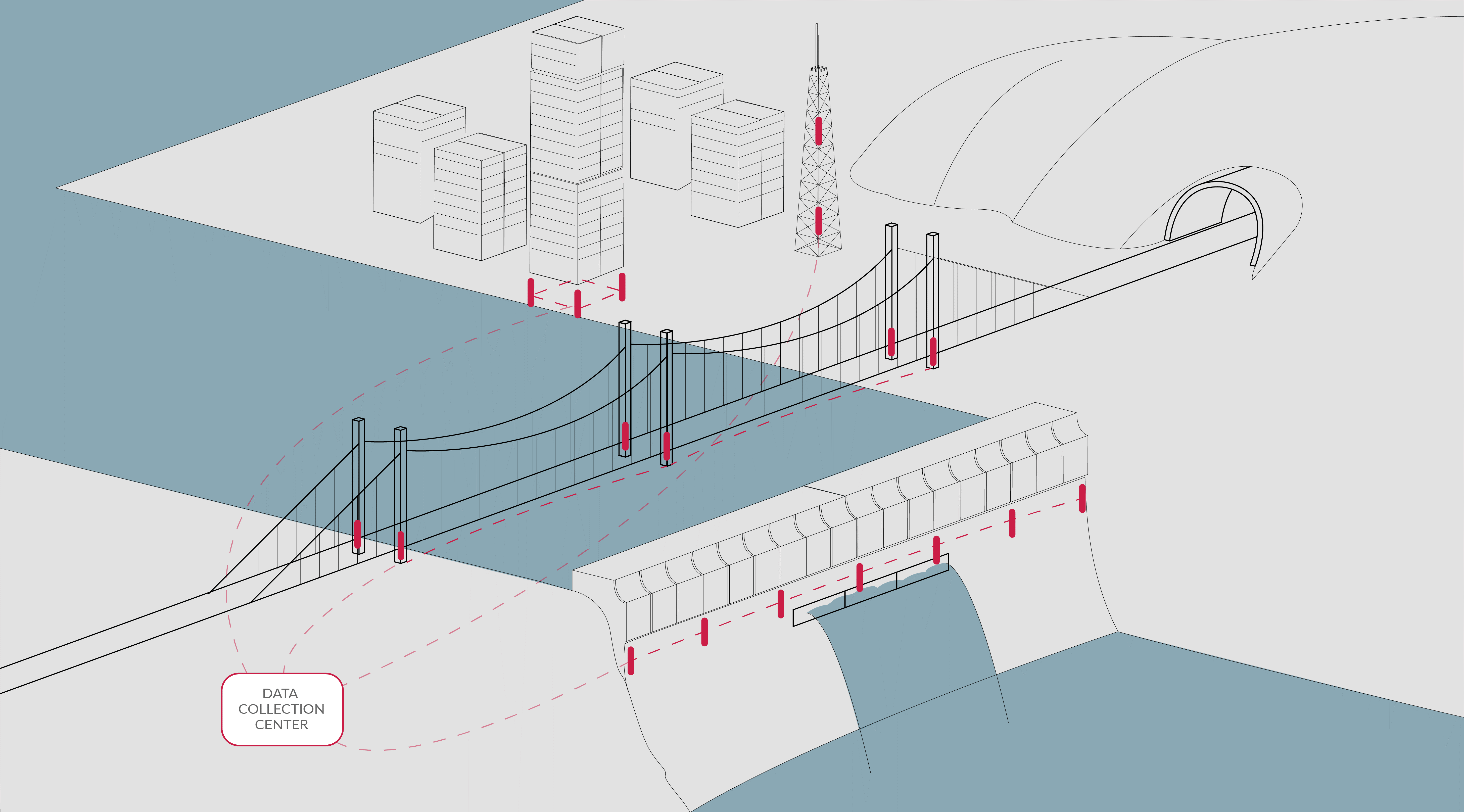

Monitoring and data collection system

Structural health monitoring (SHM) systems have been widely considered as a powerful tool to track structural performance in real-time by using different types of sensors. It allows for making timely decisions regarding structural maintenance by continuous monitoring of sensor data.

Anomalies, which do not comply with the expected patterns and characteristics, are valuable in the warning of unusual events (e.g. vehicle accidents, ship collisions, or earthquakes) and structural damage, allowing maintenance operators to make the correct intervention.

Therefore it is highly desirable to develop an accurate automated approach for anomaly detection in SHM data. Furthermore, since the data is continuously collected, anomaly detection calculations are performed instantly.

ULTRAXIS works with outstanding specialists from technical universities in various countries to develop systems for analyzing the data collected by our sensors.

The ULTRAXIS monitoring and measuring system, which includes ultrasonic sensors, is designed for the continuous testing of building stability and sending alarms in case of any emergency.

· Individual measuring devices are connected to a central computer through an interface that can take measurements from up to 100 sensors simultaneously

· Sensors are galvanically isolated and can be connected via USB

· The information transmission system encoded in the signal frequency enables transmission over considerable distances (up to 2 km without additional amplifiers) and is characterized by high interference resistance

· Ultrasonic sensors can be connected to the computer system also through local interfaces, which send measurement results via an RS485 bus

For remote measurement locations, the sensors are powered by batteries and connected to the central computer /cloud via various wireless techniques.